It can help assess any consumer demands or preferences to help you forecast demand more accurately. For instance, with the hockey helmet example, companies are likely to see an uptick in demand in the fall and winter seasons when hockey is primarily played. The spring and summer, conversely, are likely to be the times of the year when there’s less demand for hockey helmets and other hockey equipment. Managing reorder points effectively and efficiently can go a long way toward appeasing your customers and also reducing overhead costs. In terms of reducing overhead, you don’t want your company to have more inventory in stock than what can be sold in a timely manner. At the same time, it can be a cost burden for your company to restock inventory every time you completely run out.

What is the Reorder Point Formula?

The market landscape and customer demand patterns are dynamic, necessitating ongoing monitoring and adjustment of the reorder point. Manufacturing companies should regularly review and update their reorder points based on changes in demand, lead times, service level objectives, and any other relevant factors. This proactive approach ensures that the reorder point remains aligned with the business’s evolving needs. Suppose a retail store sells a popular product with an average daily demand of 50 units. The lead time for replenishing stock is seven days, and the store aims to maintain a 95% service level, ensuring that the product is available to customers in most instances. By utilizing statistical methods, the store calculates that the standard deviation of daily demand is 10 units.

Understanding Reorder Points (ROP)

If your demand forecasting isn’t accurate, you can miss the signs that help you plan safety stock and reorder what is rop in business points for impending shifts in demand. Supply chain challenges also pose a problem in your inventory planning. Making sure you’re notified of potential issues as soon as they happen can help you find solutions faster.

Don’t rely solely on the reorder point formula

As one can see there are several advantages to becoming an ROP including greater access to HOA Accounting trading products as well as potentially higher payouts due to increased premiums on securities transactions. An ROP is an individual who holds a designation from FINRA that indicates he or she has met certain requirements established by this regulatory agency. To obtain this designation, they must pass a series of tests related to their knowledge of securities trading and regulations. This includes topics such as pricing of options contracts, order execution techniques, best practices related to option trading strategies, and so on. Furthermore, these individuals must also demonstrate experience in dealing with customer accounts or portfolio management when taking these examinations.

- Newspaper Inserts, also known as Free Standing Inserts (FSIs) are separate advertisements on a sheet that feature promotional offers, coupons, catalogs, and special offers.

- Choosing the right publication for your ads helps attract more prospects and target the right audience for your product or service.

- The ultimate goal of the reorder point is to maintain an amount of inventory at a level that can always meet customer demand without having more than is realistically possible to move.

- We have already seen what the reorder point is and what the formula is.

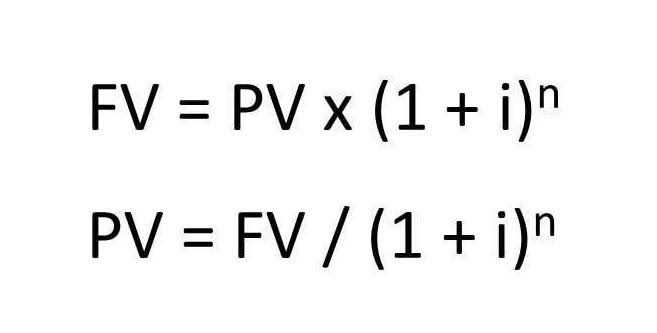

This article gives you the reorder point formula and how to calculate your reorder point. SAP Business One is a trusted ERP backbone for mid-market companies worldwide. It helps manage finance, operations, and inventory http://www.biendeks.com/2023/07/11/what-are-the-accounting-principles-assumptions-and/ in one centralized platform.

Having enough stock ensures customer demand can be met without any hiccups or cancellations – happy customers equal healthy profits. A less reliable supply chain requires a higher Reorder Point to buffer against disruptions, often resulting in increased safety stock or longer lead times. Businesses can address these challenges by diversifying suppliers, implementing performance monitoring, or opting for local sourcing to reduce uncertainties. Knowing the reorder point and following it as part of your company’s inventory management can help strike that perfect balance between having too much inventory and too little inventory. Too much inventory, and you’re spending money on storing and warehousing it. There’s also the chance that customer preferences shift and your product becomes obsolete before you have a chance to sell it all.

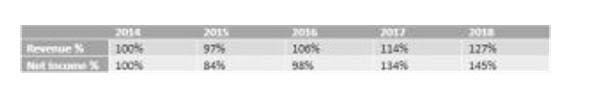

As businesses navigate increasingly complex and volatile markets, there’s a shift towards dynamic and adaptive ROP management driven by technological advancements and data analytics. Traditionally, companies used a static min/max approach, setting fixed minimum and maximum inventory levels, which often resulted in suboptimal inventory management. The transition to dynamic systems involves real-time data integration, machine learning, multi-factor analysis, automated decision-making, and scenario modelling. These systems optimise safety stock based on service level objectives, demand and lead time variability, and other factors.

Products

By carefully considering these factors and balancing them against each other, you can determine an optimal level of safety stock that minimizes risks without unnecessarily tying up capital and resources. By taking these patterns into account, you can tailor your ROP to align with these fluctuations, ensuring that your inventory levels are optimized throughout the year. Delivery times may decrease, which is good, due to improvements in supply chain efficiency, change of suppliers, etc. In this case our average lead time is 17 because we take the average lead times of the last 3 orders. Stockouts lead to longer wait times for customers, which nobody likes.